Thus W ρ K e A B ln Flv C ln Flv 2 d ln Flv 3 E ln Flv 4. Provided Rotary Dryer dimensionφ2020m.

4 Spin Flash Dryer From Devahastin S Ed Mujumdar S Practical Download Scientific Diagram

Following dimensions for the drier are chosen.

. 622 Sludge Pump Types and Applications There are specific considerations to be borne in mind in the use of different types of pumps for handling sludge. Design also permits the use of the highest possible drying temperatures and in contrast to other dryers is not sensitive to wide variations in material size moisture content or throughput. Force is dependent on velocity cross sectional area density and viscosity.

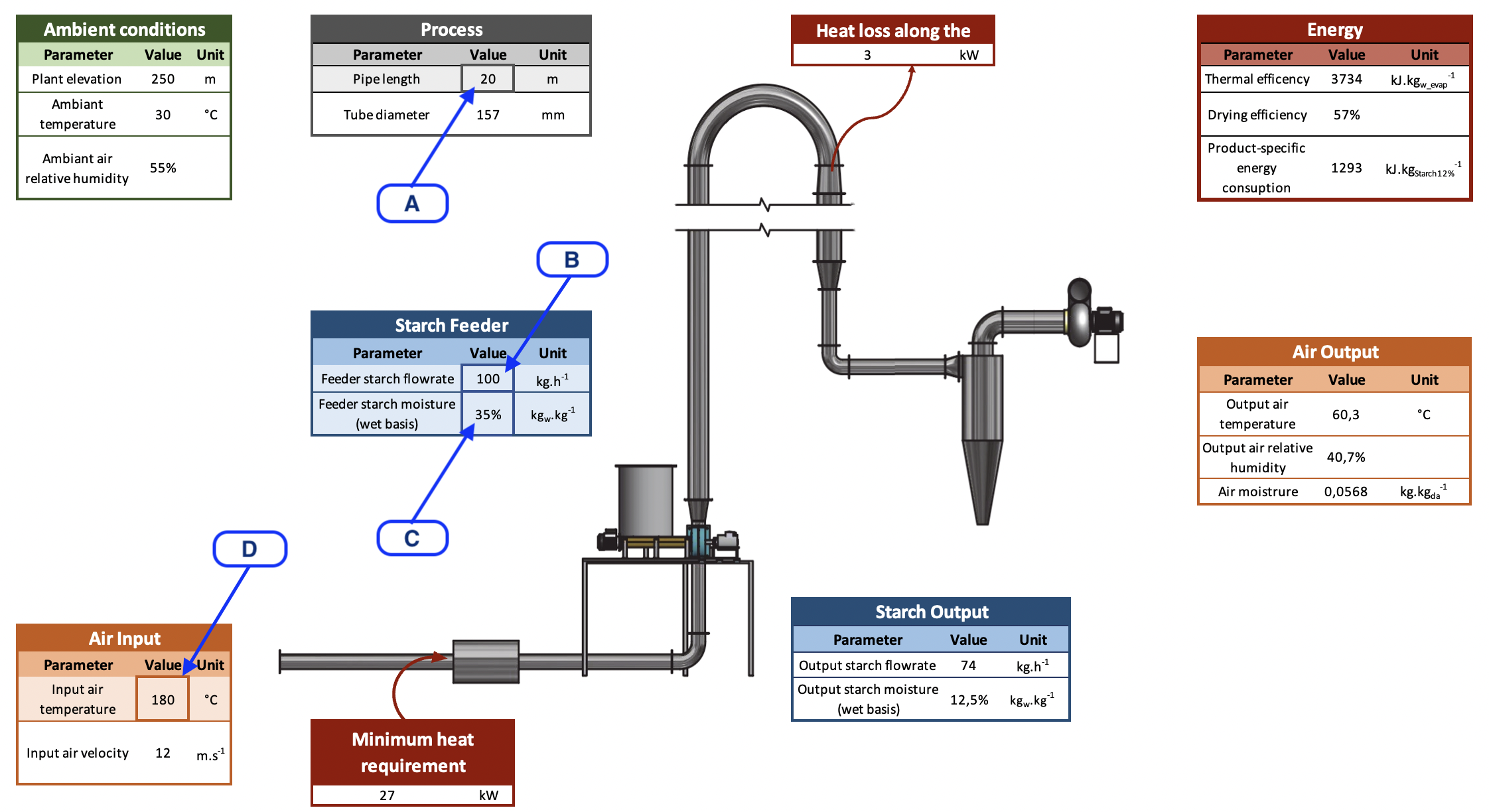

Other drying softwares are suitable for process analysis and simulation. Diameter of dryer 209 m. Design basis The following were the physico-chemical properties of cassava starch used as input variables to determine parameters of interest necessary for the design of a column flash drying unit.

Results from each calculation can be displayed in report format. Therefore Î Thus is a function of the particle Reynolds number. The dryer senergy usemust also beseen in the context of the complete process and indeed of the site as a whole.

Î Re d vAπ μ 1 2 2 drag D Vd F C ρAv fC bD Re 0 2 Re 1 2 D Dc Vd F Cf ρAv C D 8 3Re c K gR d f fF vA adragd V 0ρμ. Selected dryer type so the set of design param-eters or assumptions is fulfilledthis is the com-mon design problem. Mechanism prior to design work is strongly recommended.

4 4 V Therefore D AD π π v perm ρV Demisters should take care of 4 or less of the 5. Figure 2shows how a high-performance dryer can produce 1950 lbs 890 kg of dried material in a 24. Ad Get Flash Dryers Equipment Within 24 Hours Or Consult With Industry Experts.

They are inherently cocurrent dryers with the hottest air contacting the wettest product. The criteria is that 5 of the liquid is entrained. Examples are the DrySPECC2 and DrySim designed by NIZO Food.

Evaporation systems Gong and Mujumdar 2008 dryPak for dryer design calculations for various gas-solvent systems Pakowski 1994 and DrySel for dryer selection marketed by Aspen Technology. Design calculations establish minimum guidelines and requirements for generating electrical calculations on projects. If the throughput of the dryer is 60 kg of wet product per hour drying it from 55 moisture to 10 moisture the heat requirement is.

Software is also available for steam heating. One key tool is pinch analysis Section 142 which shows the temperatures at which the dryer heat load is required and where heat can be recovered from the. Calculation of the quantity of water to be evaporated is explained below with a sample calculation.

An allotted drying time between 217 and 254 hours would require a drying air temperature between 290 and 293 Kelvin and a drying air velocity of 03 meters per second. The results prove that the dryer is most efficient when the dryer runs at 370 Kelvin and 03 meters per second when the allotted drying time is less than 217 hours. Flash drying is a continuous process with the dryer being either directly or indirectly fired.

Principles of Operation In its simplest form the cascade dryer consists of a slightly inclined rotating cylinder fitted with a series of peripheral. They operate at inlet temperatures varying from ambient dehumidified air for sensitive products to more than 1100 o F 600 o C for robust products. Electrical calculations should be made for all SPU projects that include electrical components and should be filed in the project notebook.

60 kg of wet product contains 60 x 055 kg water 33 kg moisture and. Design calculations may be made either manually or by SPU-approved computer programs. Length of transfer unit has been related to mass velocity and diameter by following relation Ltu 00064 xCp x G 084 x204 736 m.

Feed moisture content 6875 wet basis Carbohydrate content of cassava starch 2890 Protein content of cassava starch 175. To the design of extruding and tray-filling equipment for de-watered cakes it is now possible to obtain the maximum benefit of enhanced evaporative rates by using through-air circulation dryers when handling preformed materials. L 12m.

Rotary Dryer Calculation Volume calculation. Diameter of the dryer e 209 m. Mechanical drives and other general uses.

The calculations for these friction losses are illustrated in Appendix A 63. To install the Rotary Dryer Shell or to adjust the shell alignment a geometry module is also available. In drying of wet solids the following main factors which essentially are used in process design calculation of dryers should be defined in accordance with mass and heat transfer principles process conditions and drying behavior.

FLASH DRUM DESIGN ChE 4253 - Design I Dimensional analysis for drag. Length of the drier Ltu x NTU 736 x 15 1105 m. Shell Installation Geometry Module.

Flv WL ρ L were obtained V V fitting experimental data. Dryer RPM Dryer power Number of Flights and Residence Time. Dryer calculations unless it can be converted to the.

Cfd Modeling Of Heat Transfer And Flow Field In Spin Flash Drying Process Request Pdf

Schematic Diagram Of A Flash Dryer Download Scientific Diagram

1 Simple Flash Drying System Download Scientific Diagram

Pilot Flash Dryer Flash Drying Model Rtb Scaling Flash Drying

Flash Dryer Design Tools Rtb Scaling Flash Drying

Flash Dryer Design Tools Rtb Scaling Flash Drying

Xsg Series Spin Flash Dryer Changzhou Changhang Drying Equipment Co Ltd

0 comments

Post a Comment